Application:

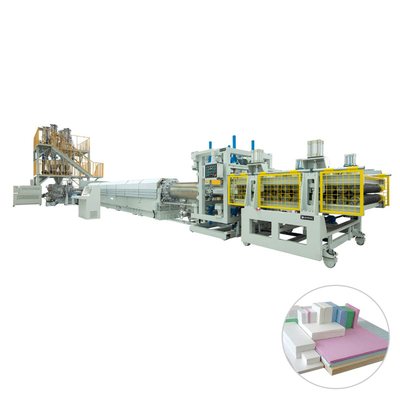

XPS Form Board

Plastic Processed:

Polystyrene

Condition:

New

Screw Design:

Double-screw

Twin Screw Type:

Co-rotating Parallel Twin-screw

Screw Material:

38CrMoALA

Screw Diameter (mm):

110-300mm

Screw L/D Ratio:

40:1

Screw Speed (rpm):

200 Rpm

Showroom Location:

None

Voltage:

Customized

Dimension(L*W*H):

Customized

Power (kW):

700

Weight:

Customized

Warranty:

1 Year

Key Selling Points:

High Quality

Applicable Industries:

Manufacturing Plant, Building Material

Marketing Type:

Hot Product

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, PLC, Pressure Vessel, Engine, Gearbox, Screw, Other

Product Name:

XPS Production Line

Final Product:

XPS Foam Board

Width Of XPS Foam Board:

450-1250mm

Thickness Of XPS Foam Board:

20-150mm

Automatic Grade:

Automatic

Transformer Required:

300-1200KVA

Blowing Agent:

CO2/Enathol/DME/HCFC/HFO/PROPANE

After-sales Service Provided:

Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

None

Certification:

ISO CE

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!