Applicable Industries:

Garment Shops, Building Material Shops, Machinery Repair Shops, Food & Beverage Factory, Restaurant, Home Use

Showroom Location:

Turkey, United Kingdom, United States, Germany

Condition:

New

Product Type:

Stone Paper Making Machine

Processing Type:

Paper Making&Single Screw Extrusion

Voltage:

220V/380V

Power:

1000kw

Dimension(L*W*H):

36000X4500X8000mm

Weight:

80 Kg

Warranty:

1 Year, 1 Year

Production Capacity:

100

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Marketing Type:

Ordinary Product

Warranty Of Core Components:

1 Year

Core Components:

PLC, Pressure Vessel, Engine, Gear, Motor, Pump, Bearing, Gearbox

After-sales Service Provided:

Overseas Service Center Available, Free Spare Parts, Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support

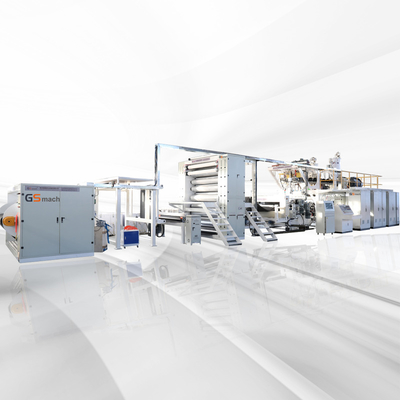

Machinery:

Sustainable Stone Paper Extruder

Raw Material:

PE+CaCO3

Output Paper:

350-500kg/h

Name:

Stone Paper Casting Line

Application:

Paper Industry

Feature:

Limestone Paper Machinery

Color:

Customized Color

Machine Type:

Semi Servo

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Egypt, Turkey, United States, Germany, Saudi Arabia, Argentina

Certification:

CE ISO9001

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!