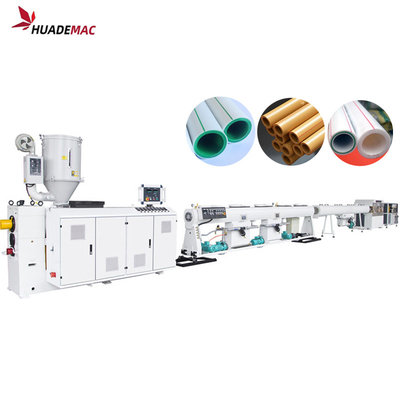

Application:

PIPE

Plastic Processed:

PE, PP, HDPE/PP

Condition:

New

Screw Design:

Single-screw

Screw Diameter (mm):

65 Mm

Screw L/D Ratio:

33

Screw Speed (rpm):

36 Rpm

Showroom Location:

Pakistan, Kenya, Algeria, Sri Lanka, Romania, Ukraine

Voltage:

380V/50HZ

Dimension(L*W*H):

4500

Power (kW):

98

Weight:

3T

Warranty:

1 Year

Key Selling Points:

Competitive Price

Applicable Industries:

Hotels, Building Material Shops, Manufacturing Plant, Construction Works , Energy & Mining

Marketing Type:

New Product 2020

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Motor, Pump, Gearbox

The Inverter:

ABB

Contactor:

Schneider

The Temperature-controlled Meter:

Omron

Automatic Grade:

Fully Automatic

Power(W):

45

Motor:

Siemens Beide

Inverter:

ABB Brand

Finished Products:

PP PE PPR PC Pipe

After-sales Service Provided:

Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support

After Warranty Service:

Video Technical Support, No Service, Online Support

Local Service Location:

Pakistan, Thailand, Kenya

Certification:

CE ISO

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!