Application:

PIPE

Plastic Processed:

PE, PP, PVC

Condition:

New

Screw Design:

Single-screw, Single Screw

Screw Material:

38CrMoALA, 38CrMoAl

Screw Diameter (mm):

65

Screw L/D Ratio:

28:1

Screw Speed (rpm):

35 Rpm

Showroom Location:

Egypt, Turkey, Morocco, Algeria, South Africa, Ukraine

Voltage:

380V 50HZ

Dimension(L*W*H):

30M*5M*3M

Power (kW):

110

Weight:

17

Warranty:

1 Year

Key Selling Points:

Automatic

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Printing Shops, Construction Works , Food & Beverage Shops, Advertising Company

Marketing Type:

New Products

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Motor, Pump, Gear

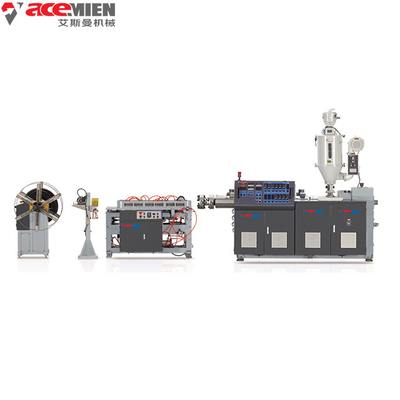

Name:

Plastic Pipe Making Machine

Usage:

Pipe Making Machine

Screw Speed:

35rpm

Brand Name ::

Acemien

Certification:

CE